Successful ammonia combustion in MAN B&W two-stroke engine marks ‘historic’ step for company and maritime sector

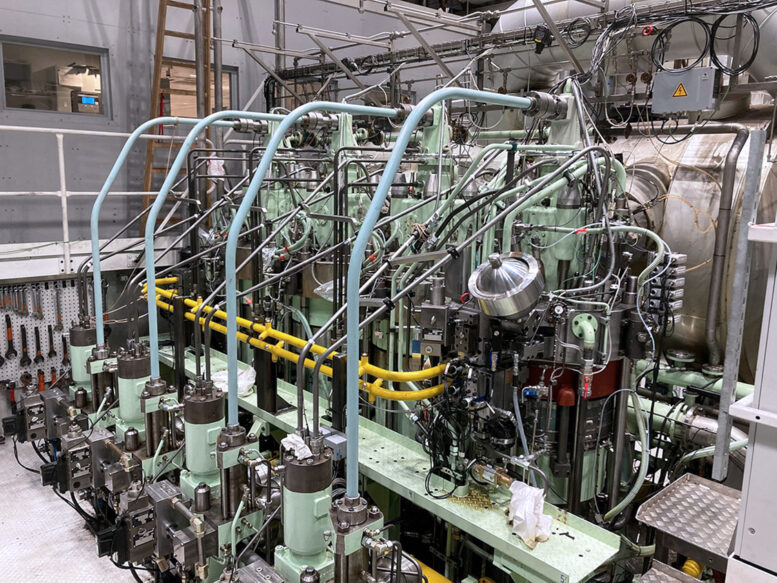

MAN Energy Solutions has announced the successful first running of a test engine on ammonia at its Research Centre Copenhagen (RCC). The company reports the successful combustion was performed on a MAN B&W 2-stroke 4T50ME-X type and produced positive results with particularly promising data regarding pilot-oil amount and combustion stability.

Gunnar Stiesch, Chief Technical Officer, MAN Energy Solutions, said: “This marks a major milestone on our road to developing a full-scale two-stroke ammonia marine engine. It’s been a historic week for our team at the RCC where a lot of groundwork and research has now paid off and we have gained a deep understanding of ammonia’s unique characteristics as a marine fuel, as well as its effects on fuel supply and safety systems. This successful combustion represents yet another, important step towards decarbonizing the marine market and bringing big things to zero.”

MAN Energy Solutions reports that safety has been of paramount importance at all stages leading to the new milestone. Precautions taken due to the fuel’s inherent characteristics include the construction of a custom-built ‘cold hall’, which can contain ammonia vapor in the unlikely event of a leak with the activation of a water screen. Robust safety features from the company’s existing dual-fuel portfolio, such as double-walled piping and system ventilation, have also been built into the ammonia engine’s design.

Brian Østergaard Sørensen, Vice President and Head of Research & Development, Two-Stroke at MAN Energy Solutions, said: “This is groundbreaking for both our company and the maritime industry as a whole. We know we still have a lot of hard work ahead and, over the following months, will execute a testing program that will study aspects such as heat-release, ignition, safety, pilot-oil energy fraction, NOx and N2O emissions. We then plan on rebuilding the test engine from one cylinder capable of running on ammonia to a full-scale test engine running on ammonia around the end of 2023 or in early 2024.”

MAN Energy Solutions states it broadly expects to hold its delivery timeline for the first ammonia engine, with subsequent operation onboard a commercial vessel around 2026.

Bjarne Foldager, Head of Two-Stroke Business, MAN Energy Solutions, said: “Interest in this breakthrough has been overwhelming. However, while we provide the decarbonizing technology, the maritime industry must show the will to implement it. Now it’s up to the International Maritime Organization (IMO) to establish clear regulations that ensure that maritime actors are not penalized for choosing carbon-neutral fuels. At MAN Energy Solutions, our expectations for ammonia are positive owing to its predicted lower production cost compared to other, relevant e-fuels; we foresee around 27% of fuel used onboard large merchant-marine vessels to be ammonia by 2050.”

Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions, said: “The first MAN B&W ammonia engine will be a 60-bore engine, which will be applicable to a very wide range of vessel types. The interest in this engine is very high and we have received many queries across basically all large merchant-marine vessels. MAN Energy Solutions expects a quick uptake of ammonia-fueled engines towards the end of the current decade.”

Project steps. The ammonia engine R&D project started in 2019 with a pre-study and investigation of ammonia combustibility. The following year, a second test-engine arrived in Copenhagen, enabling a parallel-test engine setup with different fuels at RCC; HAZID workshops on the engine concepts were performed simultaneously.

In 2021, the ammonia fuel-supply system and auxiliary systems were specified with the highest possible focus on safety.

In 2022, the installation of the same systems at RCC with instrumentation for test engine No. 1 for 1-cylinder ammonia testing was initiated.

In 2023, ammonia bunkering and service-tank facilities were built with all auxiliary systems enabling a full containment of ammonia in the unlikely event of a leak. Similarly, all auxiliary systems were initially tested with water, followed by ammonia.