A new series of Damen vessels offers flexibility and reduced total cost of ownership by means of modular mission modules with proven technologies.

On 8 June 2016, during the Oceanographic Survey Vessel Conference in London, Damen Shipyards Group announced the introduction of a new range of Multi-Role Auxiliary Vessels (MRAV). The common theme running through the series was the provision of a basic platform offering reliable and cost-effective multi-role potential and hydrographic survey capabilities to naval clients.

With the addition of supplementary modular mission equipment, this new family of Damen vessels can be mobilised in numerous, mainly littoral, naval tasks such as: explosive ordnance clearance and disposal, diving operations, torpedo recovery and overhaul, ROV and UAV deployment, SAR, coastal infantry and submarine support. The largest version of the range will be able to operate worldwide, on the ocean as well as in littoral waters. This ship has additional capabilities such as disaster and humanitarian relief, oceanography and naval training support.

The introduction of flexible concepts allows as many functions as possible to be included into a range of smaller vessels without reducing the effectiveness and capacity of the fleet while maintaining the benefits of modularity. This is Damen’s ambition with this new family of vessels. “To this end, plug-and-play containerised kit for many support tasks contribute considerable adaptability to a particular mission,” explains Damen Shipyards Gorinchem’s Principal Naval Advisor Jan van der Burg, a retired Vice Admiral of the Royal Netherlands Navy.

One platform – multiple tasks. “The idea behind these vessels is to create a basic platform that can assist in a variety of tasks through the selection of the required mission configuration, e.g., coastal transport, submarine support, or coastal infantry operations. The stimulus to switch from the traditional one-to-one replacement is to lower the total cost of ownership without losing capability and capacity,” Jan van der Burg further explains.

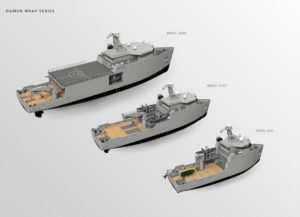

The new range of vessels consists of three different designs: the MRAV 660, MRAV 1600 and MRAV 3600. Designed for different geographic profiles, these vessels are respectively 43, 62 and 85 metres long. Hydrographic capabilities, to map the seabed for safe navigation and as a preparatory action for military operations in particular, are indispensable to navies worldwide. Depending on a naval client’s specific requirements, any type of hydrographic equipment can be integrated into these three vessels.

Minimal draught. With a draught of 1.9 metres, the MRAV 660 is suited for very shallow coastal, riverine, and inland water operations. In addition to shallow water hydrographic surveys, this vessel is capable of a comprehensive array of duties such as diving operations, EOCD support, ROV and UAV deployment, with a core crew of 8 and capacity for an additional 15 specialists.

“Damen has built up a lot of knowledge on shallow draught ship design – this is the reason we strived towards a shallow draught hull for the MRAV 660 with full confidence. The expertise of our Research Department, combined with input from our Workboats Product Group contributed to a design based upon tested design solutions,” notes Damen Design and Proposal Engineer Tim Viveen.

“The key points are to maximize displacement, minimize resistance and optimize sea-keeping characteristics for the area in which the ship will operate. The MRAV 660 has design characteristics such as an aluminium superstructure and reduced freeboard section that help to cut down on weight. In addition, tunnel ducts on the underside of the hull ensure enough water reaches the propellers,” says Tim Viveen.

Additional roles. The MRAV 1600 is designed for littoral and regional offshore operations. Its larger size allows for greater endurance and carrying capacity of the crew, mission modules, and cargo. A crew of 13 may man the vessel with capacity for an additional 30 mission specialists. The main deck can hold six standard 20-foot mission containers, and the below-deck cargo hold can store two 20-foot containers and palletised cargo.

This medium-sized vessel can take on similar hydrographic and auxiliary duties to its smaller sister vessel, with the addition of torpedo recovery and overhaul tasks in support of submarines and anti-submarine warfare units. Small-scale coastal transport and infantry support is also possible.

Global coverage. Intended for worldwide service, the capacity of the largest vessel in the range – the MRAV 3600 – allows for more than one specific mission during a deployment. Capable of hydrographic operations, both in littoral and deeper waters, this vessel also has a helideck and substantial storage capacity for other mission configurations, equipment, and cargo. Furthermore, the MRAV 3600 can serve as a base for more extensive operations such as disaster and humanitarian relief. There is accommodation for 14 core and 45 additional mission crew, and enough space on board to provide emergency hospital services for 50 to 60 people.

Advantages of modularity. One of Damen’s key aims is to reduce the pressure on a navy’s human and financial resources. The modularity of the mission modules also plays a major part in reducing this pressure: “We achieved this by combining the capabilities of specialized ships into one ship by using these add-on equipment modules which can be fitted inside standard 10, 20, or 40-foot containers; or have the footprint of a standard container. When operating multiple ships of the same family and design, the efficiency of training, crew exchangeability, and maintenance programmes are improved,” states Damen Design and Proposal Manager Piet van Rooij.

Cost results. A modular platform is inherently flexible: this allows naval clients to better react to changes in the mission environment. Modularity also has implications on the total cost of ownership: the lifetime of an individual vessel can be efficiently extended by upgrading capabilities with new equipment modules that are not integrated into the original design.

Financial advantages exist in that the MRAV range is commercially built and uses commercially available components. This is made possible because of the vessels’ non-combatant role. Van Rooij indicates that, “Using commercial off-the-shelf equipment reduces the total cost of ownership without reducing the quality of the equipment.”

Complementary design. The ship design itself has a proven background. “Damen has built many ships similar to the MRAV range for the offshore industry. This means that there will not be any unwanted surprises for the first customer of this new range,” Van Rooij elaborates.

Damen has a rich naval shipbuilding heritage, one that goes back more than a century. The new MRAV range serves to expand the company’s naval portfolio that includes larger vessels such as frigates, corvettes, LPDs, AORs, and OPVs. “These new MRAV designs are complementary to the range of ships that Damen already offers for the defense and security markets,” concludes Van Rooij. “We are currently at the stage of finalised conceptual design. Considering the next step, being more detailed in engineering while taking advantage of COTS equipment and tested designs, we are confident that the actual construction can be swiftly accomplished, with excellent quality and reliability.”

Damen Shipyards Group. Damen Shipyards Group operates 32 shipbuilding and repair yards, employing 9,000 people worldwide. Damen has delivered more than 6,000 vessels in over 100 countries and delivers some 180 vessels annually to customers worldwide. Based on its unique, standardized ship-design concept, Damen is able to guarantee consistent quality.

Damen’s focus on standardisation, modular construction and keeping vessels in stock leads to short delivery times, low ‘total cost of ownership’, high resale values and reliable performance. Furthermore, Damen vessels are based on thorough R&D and proven technology.

Damen vessels include tugs, workboats, naval and patrol vessels, high-speed craft, cargo vessels, dredgers, offshore industry vessels, ferries, pontoons, and super yachts.

For nearly all vessel types, Damen offers a broad range of services, including maintenance, spare parts delivery, training and the transfer of (shipbuilding) know-how. Damen also offers a variety of marine components, such as nozzles, rudders, anchors, anchor chains, and steel works.

In addition to ship design and shipbuilding, Damen Ship-repair & Conversion (DSC) has a worldwide network of 15 repair and conversion yards with dry docks ranging up to 420 x 80 meters. Conversion projects range from adapting vessels to today’s requirements and regulations to the complete conversion of large offshore structures. DSC completes around 1,500 repair and maintenance jobs annually. For further information, visit www.damen.com.