Swiss engine technology company WinGD is helping shipping companies to optimize engine combustion and reduce methane slip with a new intelligent dual fuel engine technology.

Intelligent Control by Exhaust Recycling (iCER) is a new technology that has been brought to the market by engine specialists WinGD. The technology, which is integrated into the company’s new X-DF 2.0 engine design, recirculates methane to reduce the amount that is left in the exhaust system and ultimately escapes into the atmosphere.

During a webinar hosted by VPO Global at the end of last year, Dominik Schneiter, VP R&D, and Volkmar Galke, global director sales with WinGD explained how the technology reduces methane slip from engines by up to 50% without affecting performance.

What is methane slip and why reduce it? Methane is a strong greenhouse gas (GHG) that is emitted from engines burning liquefied natural gas (LNG). LNG as a marine fuel has grown in popularity in recent years thanks to some of the huge advantages it offers, including the reduction of sulphur oxides (SOx), nitrogen oxides (NOx), particulate matter (PM) and carbon dioxide (CO2). Its growing availability means that it is a relatively easy fuel for shipping companies to obtain. As environmental requirements set out by the International Maritime Organization (IMO) tighten, LNG offers a viable solution to guarantee compliance.

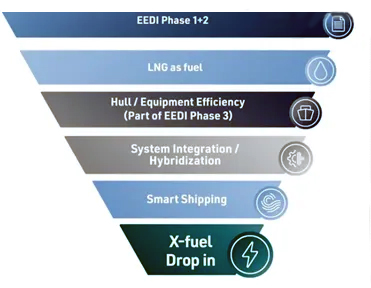

Despite its benefits, LNG is still a fossil fuel. WinGD believes that rather than being a solution for shipping’s decarbonization, LNG can be thought of as a transformation fuel while the path for alternative fuels continues to be paved. Synthetic LNG (SLNG) and bio gas, if available, could be used today to reduce GHG drastically with X-DF engines.

Figure 1. WinGD sees LNG as transformation fuel while other methods to decarbonize shipping continue their development. Photo Credit: WinGD.

WinGD’s answer to methane slip. WinGD’s goal is to provide engine technology that can both improve the environmental credentials of marine fuels available today and cope with new fuels that are expected to enter the market in the future.

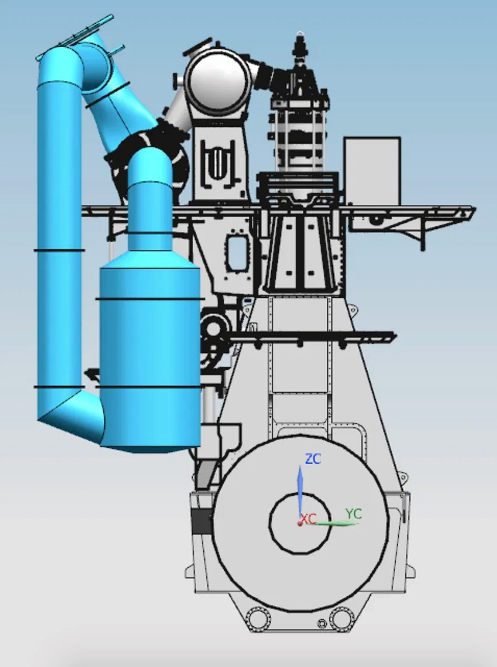

The company’s latest engine design, the two-stroke dual fuel X-DF 2.0 has already proven its capability to optimize fuel performance with the help of the innovative technology known as Intelligent Control by Exhaust Recycling (iCER).

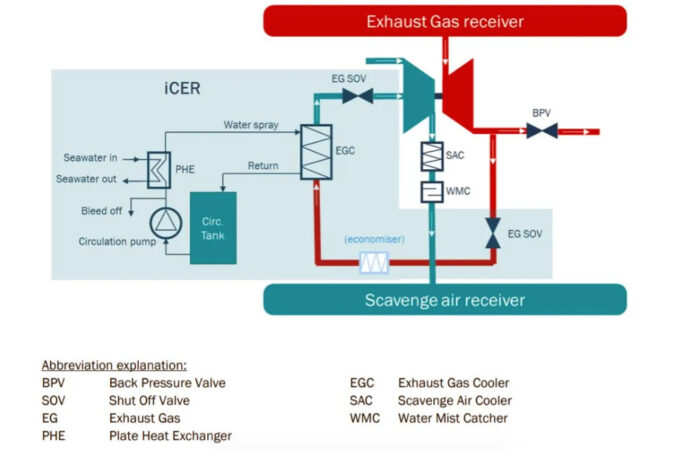

“iCER technology can reduce methane slip by up to 50%,” Mr Schneiter explained to listeners tuning in to VPO’s webinar. The iCER system works by cooling and recirculating up to 50% of the exhaust gas through a low-pressure path during operation in gas mode. This makes complete use of the turbocharger capacity when compared with a high-pressure path. A system adjacent to the engine circulates part of the exhaust gas (up to 50%) after the turbine, through an exhaust gas cooler (EGC) to the compressor inlet. The exhaust gas and the fresh air are mixed before entering the compressor wheel of the turbocharger (see figure 2).

Figure 2. The iCER system recirculates part of the exhaust gas through a low-pressure path during operation in gas mode. Image courtesy of WinGD.

In the event of iCER technology failure, the system can simply be bypassed. The iCER technology will be available for all X-DF engines as part of the new X-DF 2.0 design upgrade.

As well as reducing methane slip, the intelligent technology allows the user better control over combustion speed to improve overall engine efficiency. “By adjusting the recirculation rate of inert gas and controlling parameters like fuel admission and ignition timing, we can increase compression ratios for greater efficiency,” explained Mr Galke.

The new X-DF 2.0 engine design with iCER technology is capable of reducing fuel consumption in diesel mode by up to 5 g/kWh and energy by 4% in gas mode. NOx emissions up to IMO Tier III standards are reduced, and the release of Black Carbon, which is not currently regulated by IMO but could be in the future, is cut. According to WinGD, these additional benefits mean that the engine is prepared for the next level of IMO regulations.

WinGD’s X-DF engines offer the greatest flexibility for future fuel through the combination of both the Diesel & Otto cycle in one engine, giving the shipowner the freedom to select either cycle for the greatest efficiency in utilizing any new fuel to come.

Current orders. “We have already seen a big interest in the customer side with many systems being rolled out today,” Mr Schneiter confirmed. To date, there have been nearly 400 orders of the X-DF engine, 100 already in operation, and more than 980,000 operating hours covering 5 variable segments. According to Mr Schneiter and Mr Galke, the lengthy operational hours prove the reliability and soundness of low-pressure technology.

To improve the engine further, WinGD is continuously collecting and using onboard data to ensure the most recent feedback is used to develop the engine further. “With all this data available, we no longer have to assume, we have hard facts to help us address the energy management challenges.”

Preparing for the future. One question Mr Galke said he often hears companies ask is, “If there’s no regulation now, then why should I invest?” With increasing pressure on the shipping industry to decarbonize and achieve ambitious climate change goals, tighter regulations can be expected. Moreover, shipping companies seen to be ‘going green’ are more likely to benefit from incentives and other discounts.

WinGD’s answer is to ensure that any investment made now is also an investment for the future. It wants to provide its clients with adaptability and flexibility so that as new fuels become available and tighter regulations enter, owners and operators already have the technology to cope with whatever change the market brings.

Ammonia is expected to grow as an alternative fuel between 2040 and 2045, according to classification society DNV GL.

“The system to use ammonia, for example, is there. It doesn’t need a fundamental change in approach so ammonia could be used by an LNG engine. However, volumes of ammonia need to be increased to make up the same quantity of LNG. The engine compatibility won’t be a challenge, we can handle that. The bigger challenge is on the fuel handling and availability side,” Mr Schneiter confirmed.

“As a technology provider we put the market requirements into a product. We get a clear demand from shipping companies and owners to move into a greener energy direction,” Mr Schneiter added.

The company also introduced the ‘fuel sharing’ concept – a combustion cycle that mixes LNG and diesel to further optimize engine performance.

Source: https://vpoglobal.com/2021/01/29/reducing-methane-slip-without-compromising-on-engine-performance/