STADT is an awarded technology leader and has been in the power electronics business for more than 30 years. Through its extensive experience, focus on sustainable products and development of the patented STADT Lean Drive technology for electric propulsion of today, there have been major steps.

STADT CEO Hallvard L. Slettevoll

Hallvard L. Slettevoll founded STADT in 1985 in a family barn in his hometown Gjerdsvika, Norway. Slettevoll started developing the first generation of STADT variable frequency drives (VFD), based on bipolar transistors with Phillips PWM control and switch mode power supply. The very first VFD was delivered to a local fish-farm company located in the neighboring village.

In 1988, the second generation STADT VFD, which was based on IGBT transistors, was released. The local hydro powerplant company, Tussa, and the Norwegian telecom company, Telenor, became regular STADT clients. But STADT’s workshop (aka, the barn) burned to the ground on New Years Eve in 1992. All of STADT’s hardware was lost in the fire. STADT then moved to a new facility in Gjerdsvika, a closed-down shipyard, which offered much more space to increase production. By 1995, STADT was the first Vacon customer outside Finland, and this grew into a close cooperation over the years between STADT and Vacon. STADT started producing small 230 Vac Vacon Drives in Gjerdsvika, and used the Vacon CPU in the development of large drives for marine applications. In 1996, STADT landed a big contract with TFDS for the Coast Guard vessel K/V Tromsø for delivery of the third generation STADT VFD which was a 500 kW, 690 Vac water-cooled VFD running on a pump jet thruster. This was a big breakthrough. More contracts from TFDS came in.

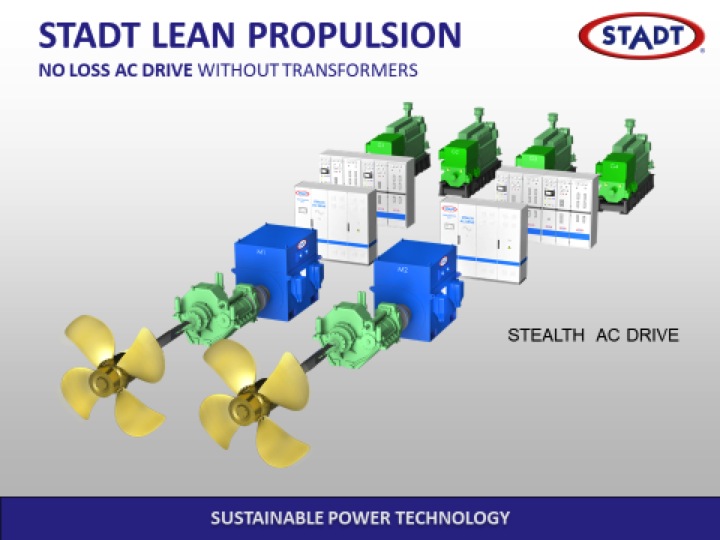

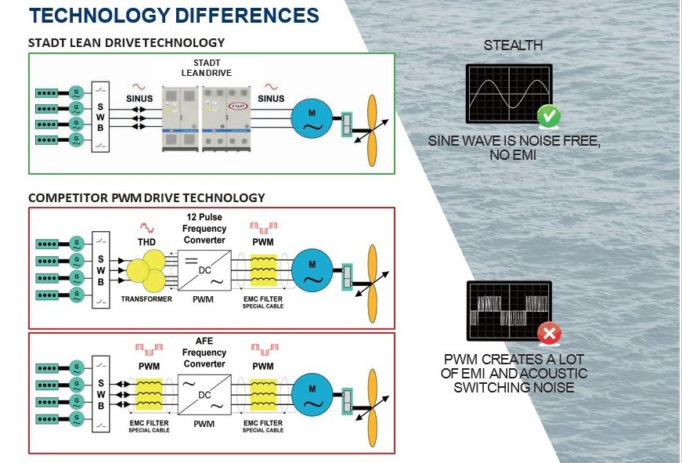

Fast-forward to June 2017, STADT AS signed a contract with the Swedish defense and security group, Saab AB. The contract was about delivery of the patented electric drive system, the STADT Lean Propulsion, to be integrated in one of the ship projects of Saab. The Lean approach used an AC Drive technology with unique performance capabilities of stealth, noise-free, extreme reliability, and lifetime cost efficient, low weight, and compact footprint. STADT CEO Slettevoll said that the contract was an important part of their strategy to bring the Lean Propulsion Design into the international naval fleet market.

In January 2018, at the Work Boat Show in New Orleans, STADT AS of Norway signed an agreement with W.A. Technical Sales to represent them in the Gulf of Mexico, as part of STADT’s worldwide expansion, targeting the maritime market globally.

The STADT Lean Drive technology, regarded as a very reliable patented technology, would be used for many kinds of electric ship propulsion solutions where power sources could be arranged in many combinations –LNG, MDO, HFO, batteries, and fuel cells. The drive technology is scalable from small to high-powered rating of 230V up to 15kV, without the use of big, heavy transformers. ABS-approved STADT Lean Drive was delivered to 16 vessels. W.A. Technical Sales CEO Bill Meyer said “the STADT technology with its remarkable track record worldwide, will have a major potential in the US in years to come.”

In 2018, Hurtigruten began connecting to shore supply in Bergen via a 1400 kW STADT ShoreCon 50/60Hz, developed and made by STADT. It enables the ships to shut down its diesel generators while staying in harbor, reducing emission, noise and fuel costs. The STADT ShoreCon can also be located onboard the vessels for increased flexibility in shore power operations. In April 2018, Topaz Master and Topaz Mariner became STADT’s clients. These new AHTSVs, equipped with STADT Lean Propulsion are state of the art vessels with reduced fuel consumption and emission. They have the highest operational safety due to tremendous redundancy in the STADT Lean Drive.

Later in 2018, STADT finalized installation of the Lean Propulsion system on the megayacht White Rabbit, built at Echo Yachts in Perth, Australia. The White Rabbit is 3000 GT, 84 meters long, 20 meters wide, built of aluminum, and has a range of 5000 nautical miles. It is the first megayacht ever built in Australia with diesel-electric propulsion, and the world’s largest trimaran superyacht. Endurance is important for such a ship.

Thus, weight, size and propulsion efficiency has been very important for this project. Two-geared STADT AC induction motors run the 2-shaft line CP propellers. This represents a highly efficient and low weight overall solution. The STADT Lean Drive technology ensures the propellers will not stop in the middle of the ocean. A noise-free ride is also essential for a megayacht. The patented Sinusoidal drive makes this possible with the Lean Drive, which is now used in naval ships for the same reason.

In March 2019, STADT signed up with a NATO-allied country to engineer new-generation naval ships using the Stealth AC Drive electric propulsion technology used in the Saab navy project. The propulsion solution is usable in any ship size due to scalability.

In July 2019, OceanXnorway by Stormbringer chose STADT Lean Propulsion as their partner for electric propulsion for their new megayacht series. OceanXnorway is based on a team of individual experts and selected collaborators. Members of the team have been engaged in various parts of the offshore industry for over 25 years in making Norway´s huge fleet of Offshore Service Vessels (OSV’s).

At present, STADT systems and products are designed for the majority of vessel types with unique features of the STADT Lean Drive to deliver a superior system for the following segments: Naval, yacht, offshore, aquaculture, seismic, fishing, cruise, merchant, tanker & bunker, passenger, and energy systems.

STADT can deliver a range of marine propulsion products: System integration, lean drive, motor, switchboard, PMS, IAS, generator, energy storage, soft starter, AC Drive, and transformers. STADT is now increasing business development activities in Southeast Asia in co-operation with the company Next Motion AS.