INTRODUCTION. This article is a product of research by the author on three types of hulls mainly used in the design of fast patrol boats, frigates, and transport vessels of the Navy.

Three Types of Hull

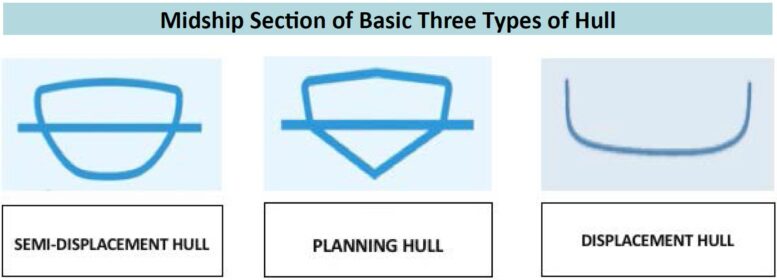

- Planning Hull – designed for motor torpedo boats that typically have a displacement of about 250 tons with a deep V midship section in order to ride on top of the water with greater speed and power.

- Main Characteristics:

- Weight sensitive; hull is made of light-weight materials;

- Deep “V” hard chime section of the hull with small draft at waterline;

- Propulsion unit consists of lightweight engine, high revolution per minute, diesel or gasoline marine engine;

- Minimum or very small freeboard margin or reserve of buoyancy;

- Not suitable in rough sea operations; limited to calm water coastal operation;

- Attainable speed in excess of 30 knots during calm sea conditions; and

- Limited capacity payload.

Fig. 1 Motor Torpedo Boats

- Semi–displacement Hull – commonly used in the design of frigates and destroyers with a sharp fine bow in order to slice through the water with reduced bow waves, and frictional resistance with greater speed between approximately 18 to 30 knots.

- Main Characteristics:

- Limited cargo capacity; hull is made of exotic light-weight materials;

- Has a sharp bow to reduce bow wave resistance between hull forward section and water frictional resistance;

- Very sleek design with limited displacement not greater than 2500 tons;

- Propulsion units consists of typical medium speed, revolution per minute of marine diesel engines;

- High freeboard typically greater than planning hull with sufficient reserve of buoyancy;

- Limited suitability in rough sea operations up to sea state 6 with wave height not greater than 2 to 3 meters high;

- Attainable speed typically not greater than 30 knots during calm sea cruising; and

- Medium capacity pay load.

Fig. 2 Combatant Ship

- Displacement type Hull – designed with greater displacement capacity and large reserve of buoyancy. Because of greater hull displacement, this type of design ploughs through the water in the speed of advance. Logistical support vessels and transport vessels are examples.

- Main Characteristics:

- Non-weight-sensitive hull made of high tensile strength materials;

- Large body section for greater cargo capacity;

- Propulsion unit consists of heavy weight, slow speed revolutions per minute; bunker oil or diesel engine;

- Very high freeboard with greater margin of reserve buoyancy;

- Very suitable for rough seas or all-weather operation at high seas;

- Attainable speed typically not greater than 24 knots; and

- Bigger capacity payload.

OBSERVATIONS

A MILESTONE IN HULL DESIGN IMPROVEMENT OF DISPLACEMENT TYPE HULL

Fig. 3a Original Hull Design of a Blunt Bow

Hull forward section is a blunt bow which creates bow waves with greater frictional resistance. Wave turbulence at the forward waterline is more pronounced.

Fig. 3b New Design with Sharp Bow and Laminar Flow

Sharp bow design replaced the blunt bow; with a reduced bow wave frictional resistance with laminar wave flow at the forward waterline at the bow.

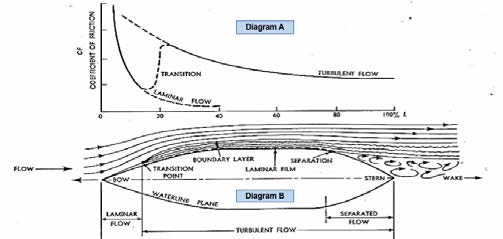

DIAGRAM OF THE DIFFERENCE OF LAMINAR FLOW AND TURBULENT FLOW OF WATER AROUND THE HULL

Fig. 3c

The resistance in Diagram A shows that turbulent flow at the bow is greater in a blunt bow which greatly affects the speed of advance of a vessel with greater fuel consumption and not proportional to the speed of advance. Whereas, a sharp bow has a laminar flow that slices through the water which is proportionate to the speed of advance, and proportionate to fuel and power usage per nautical run made good.

Diagram B shows the coefficient of friction versus the water line length of the ship’s hull; a vessel with a sharp bow shows laminar flow at the boundary layer and slices the water with less friction resistance at 20% of the waterline length. At this point, turbulence flow occurs as the sharp bow slices through the water instead of pushing the water with greater bow wave frictional resistance.

RECOMMENDATION. Bow wave frictional resistance is always the main concern of the Naval Architect in the design of vessels so as to balance the proportionate amount of power needed with the most economical means of fuel consumption per nautical mile run made good in cruising at sea. Modern tank tests and computer-generated designs can balance accurately. A hybrid design of a vessel between displacement and semi-displacement is good for economy of operation.

REFERENCES AND PHOTO CREDITS:

- https://en.wikipedia.org/wiki/Bacolod_City-class_support_vessel

- https://thediplomat.com/2015/08/rok-navy-launches-new-guidedmissile-frigate-to-deter-north-korea/

- https://maritimereview.ph/the-saga-of-q-111-luzon-the-secondphilippine-motor-torpedo-boat-that-served-three-navies/

- Modern Ship Design by Thomas Gilmer.

ABOUT THE AUTHOR

CAPT Tomas D Baino is a registered naval architect and civil engineer in the Professional Regulation Commission in the Philippines. He was a former instructor on Basic Naval Architecture Stability and Trim at the Naval Officer Qualification Course at the Naval Training Command of the Philippine Navy and Basic Naval Architecture at the Philippine Military Academy, Baguio City. Likewise, his part time job is also to teach Basic Naval Architecture at NAMEI Polytechnic Institute. He was the former Commanding Officer of the Naval Shipyard, Philippine Navy and was involved in co-production of the 78-Foot Gunboat with Halter Marine Shipyard of USA and Patrol Craft Escort Refit Program of the Philippine Navy and Joint United States Military Advisory Group. Upon his retirement from the NAVY in 2004, he served as a

consultant with BFAR for the acquisition of Fishery Monitoring Control Vessel from Spain, and also with DOTr for the acquisition of 12 Multi-Role Response Vessel for the PCG under JICA Loan Grant. He served with the Development Bank of the Philippines Maritime Leasing

Corporation in 2006 for local construction of RORO Vessels. He earned a post graduate diploma in Naval Architecture at the University College of London specializing in Submarine Design under the sponsorship of UK Ministry of Defense and training in Hydrodynamic with Defense Evaluation Research Agency also in UK. He also had undergone an orientation seminar with Blomh and Voss on MEKO Warship Design and Construction in Hamburg, Germany.