INTRODUCTION

Don Felix B. Padilla was the first Filipino to graduate as a Naval Architect and Marine Engineer from the Massachusetts Institute of Technology (MIT, USA).

Engr. Felix B. Padilla – NAMEI Founder

Don Felix returned to the Philippines to share his learning and knowledge with his country and established the Naval Architecture and Marine Engineering Institute (NAMEI) in 1947. He wanted to give his fellow Filipinos the chance to work for the progress and development of the country through the Maritime Sciences (MarSci). This was his dream.

Don Felix passed away in 1982, but his dream continues. NAMEI’s goal is to make economic advancement accessible to the ordinary Filipino through affordable quality education. For over 50 years, NAMEI has trained many young Filipinos to become successful professionals in the maritime industry. Today, NAMEI is recognized as a pioneer in maritime education, imparting up-to-date technical skills to the Filipino youth and leading them towards a bright and prosperous future.

Vision

By providing education that meets global standards yet remains affordable to the Filipino people in accordance with its aim of serving God and mankind, NAMEI Polytechnic Institute works towards an economically, technologically, and morally enlightened and prosperous Philippines.

Mission

- To provide quality education and holistic personal development that enables students to reach their full potential;

- To maintain an effective updated curriculum for the attainment of desired learning competencies; and,

- To build an environment that promotes good morals, human dignity, and social responsibility.

Goals

- Students that possess the knowledge, skills and values necessary for a productive and successful career.

- Achievement of national and international needs and standards through our well-trained graduates.

Some Notable NAMEI Alumni

- Engr. Bernardo Ebeo, former director, Naval Sea Systems Command Management Office for the Western Pacific at Pearl Harbor;

- C/E Bienvenido Maranan;

- Engr. Samuel Lim, president, FAME & SONAME;

- Engr. Rosalio Quirante, currently PRC examinee;

- Engr. Cipriano Bautista, former mayor of Navotas;

- Engr. Martin Mayuga, Naval Architect British Columbia Ferries Vancouver Canada;

- And many others in the MARINA local and foreign shipbuilding and repair industry.

NAVAL ARCHITECTURE

Naval architecture, or naval engineering, involves basic and applied research, design, development, design evaluation and calculations during all stages of the life of a marine vehicle. Preliminary design of the vessel, its detailed design, construction, trials, operation and maintenance, launching and dry-docking are the main activities involved. Ship design calculations are also required for ships being modified (by means of conversion, rebuilding, modernization, or repair). Naval architecture also involves formulation of safety regulations and damage-control rules and the approval and certification of ship designs to meet statutory and non-statutory requirements.

Hydrostatics

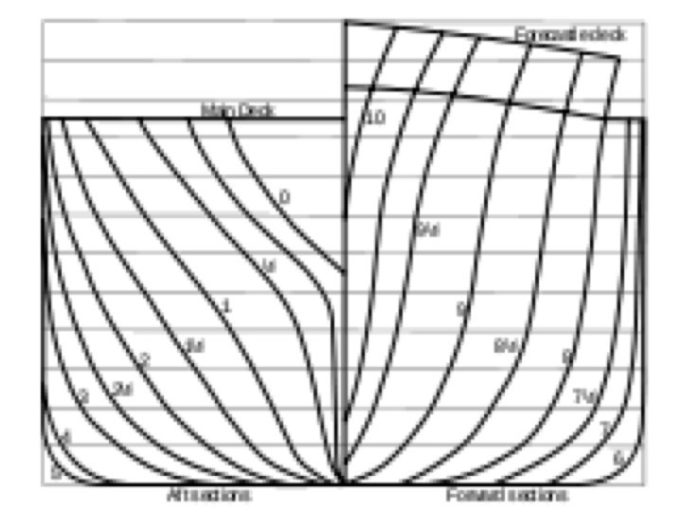

Body plan of a ship showing the hull form

Hydrostatics concerns the conditions to which the vessel is subjected while at rest in water and to its ability to remain afloat. This involves computing buoyancy, displacement, and other hydrostatic properties such as trim (the measure of the longitudinal inclination of the vessel) and stability (the ability of a vessel to restore itself to an upright position after being inclined by wind, sea, or loading conditions).

Hydrodynamics

Hydrodynamics concerns the flow of water around the ship’s hull, bow, and stern, and over bodies such as propeller blades or rudder, or through thruster tunnels. Resistance – battling motion in water is primarily due to flow of water around the hull. Powering calculation is done based on this. Propulsion – moving the vessel through water using propellers, thrusters, water jets, sails etc. Engine types are mainly internal combustion. Some vessels are electrically powered using nuclear or solar energy. Ship motions – movements of the vessel in seaway in response to waves and wind. Controllability – maneuvering, controlling, and maintaining position and direction of the vessel.

Flotation and stability

While atop a liquid surface a floating body has 6 degrees of freedom in its movements, these are categorized in either rotation or translation.

- Fore and aft translation is termed surge.

- Transverse translation is termed sway.

- Vertical translation is termed heave.

- Rotation about a transverse axis is termed trim or pitch.

- Rotation about a fore and aft axis is termed heel or roll.

- Rotation about a vertical axis is termed yaw.

Longitudinal stability for longitudinal inclinations, the stability depends upon the distance between the center of gravity and the longitudinal meta-center.

While a body floats on a liquid surface it still encounters the force of gravity pushing down on it. In order to stay afloat and avoid sinking, there is an opposing force that acts against the body known as hydrostatic pressures. The forces acting on the body must be of the same magnitude and same line of motion in order to maintain the body at equilibrium.

Structures

Structures involve selection of material of construction, structural analysis of global and local strength of the vessel, vibration of the structural components and structural responses of the vessel during motions in seaway.

Arrangements

Arrangements involve concept design, layout and access, fire protection, allocation of spaces, ergonomics and capacity.

Construction

Construction depends on the material used. When steel or aluminum is used this involves welding of the plates and profiles after rolling, marking, cutting, and bending as per the structural design drawings or models, followed by erection and launching.

SHIPBUILDING and REPAIR INDUSTRY IN THE PHILIPPINES

Herma Shipyard, Mariveles, Bataan

Cebu Shipyard, Mactan

SHIPBUILDING and REPAIR AS PART OF DEFENSE INDUSTRY IN FOREIGN COUNTRIES

Warship Construction and Retrofit

Warships are the chief instruments for a nation to extend its military might, by protecting own interests like fleet and offshore platforms against enemy attack. They prevent the enemy from using the sea to transport their military forces and are also used to blockade, i.e., in attempts to prevent an enemy from importing by sea the commodities necessary for his prosecution of the war by blockading and attacking the enemy’s merchant shipping. Offensive actions against the enemy’s military installations, ports and economic/strategic targets form another important role. The operations to be performed by a warship make it necessary that it has to be sleek and fast moving, besides being of high maneuvering capabilities. When these features are considered as the basic requirements, the resulting structure will have to be light, and at the same time it has to withstand weapon-imparted loads like impacts due to recoil, blast, explosions, etc.

Categorization of Warships

In order to accomplish the above functional objectives, naval ships have been designed to be faster and structurally stronger than merchant ships, and thus be capable of carrying offensive weapons. Modern combat ships have generally been classified into five major categories:

- Ships with landing/take off facilities and hangars for aircraft viz. aircraft carriers and landing platforms.

- Vessels that fight primarily with guns or with rocket-propelled missiles and guns which form part of the carrier escort force. A Corvette is a small single-screw ship designed for convoy duties. A Frigate is a longer and improvised version of a Corvette. A Destroyer is a fast and slender, and is generally equipped with torpedoes, anti-submarine equipment, medium-calibre, antiaircraft guns, and guided missiles as their chief weapons. A Cruiser is large, fast, moderately armed, and displacement is in between that of an aircraft carrier and the Destroyer.

- Ships that take part in active combat and perform miscellaneous tasks e.g., anti-submarine warfare, amphibious operations.

- Submarines that mainly operate from underwater using mines, torpedoes, and depth charges, and missiles.

- Miscellaneous ships like, fleet tankers, survey vessels, etc.

- Structural Features of Warships

Warships above 60 m in length are usually longitudinally framed, with a transverse frame at every standard frame spacing. Special quality steels like B quality steel conforming to NES 791, 10XSND, DS40, AK 25 and, HY 80 are used for the construction of warships. The structure should withstand shock and blast loads in addition to the conventional loads.

Structural Behavior and Failure Modes

The possible modes of failure caused by slamming in heavy seas can be divided into two groups: primary failures, where the ship’s survival is threatened and secondary failures, where the continuance of the voyage in the normal mode of operation is impaired. Primary damage modes consist of local yielding of forefoot plates due to excessive bending at hard points and rupture of welded joints, plastic buckling of bow and forefoot plates, yielding of frames in the highly loaded areas of the hull, yielding and possible rupture of hull girder plates caused by the severe vibratory motion of the entire ship, and low-cycle fatigue in highly stressed locations. Secondary modes of failure can be shock damage to navigational and communication systems, shock damage to piping and electrical transmission systems.

Design Philosophy

The motto of fighting ships all around the world is “To Float, To Move and To Fight.” The naval design spiral commences with the threat analysis for developing a variety of conceptual solutions, ranging from the conservative to the abstract and encompassing the latest technological advances and developmental research. Warships are generally sleek, slender with V shaped sections and block coefficients below 0.5, compared to fuller forms and higher values in the range of 0.8 to 0.9 for tankers, around 0.75 for general cargo ships etc. The ratios like LIB, L/D, B/D, B/T etc. of a warship also vary significantly from a commercial ship. Warships normally operate in the higher Froude number regime, and the hydrodynamic design of the hull is primarily aimed at achieving higher speeds with the minimum power. In case of damage in action or otherwise, it is desirable that the ship retains some fighting ability, or at least allows sufficient time for the crew to disembark safely. Warships are conforming to Naval Engineering Standards (NES). NES 154 [30] defines the structural strength standards in the design, construction and modification of surface warships and the basis for approval and acceptance. So far, no clear recommendations or guidelines based on probability methods are prescribed in NES. Introduction of classification society rules is the latest development in warship design. The rules are based on the concept that static and dynamic loads experienced during normal operating conditions should not compromise the structural integrity, water tightness, and general safe operation of the ship. The formulae in the rules for the scantlings of structural members like stiffeners, beams, girders, etc. are normally based on elastic or plastic theory using simple beam models supported at one or more points, and with varying degrees of fixity at the ends, associated with an appropriate concentrated or distributed load.

MARINE PROPULSION

Marine propulsion is the mechanism or system used to generate thrust to move a ship or boat across water. While paddles and sails are still used by some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or engine turning a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

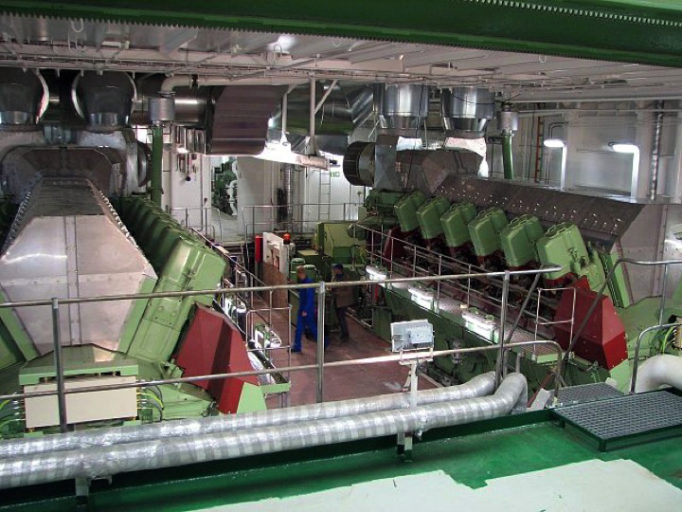

Marine Propulsion Plant

The marine propulsion plant is the heart of the ship that provides the move function at any weather condition at the most economical means. This is the heaviest and biggest component of a ship’s systems.

References:

- https://en.wikipedia.org/wiki/NAMEI_Polytechnic_Institute

- https://www.google.com.ph/search?rlz=1C1CHBD_enPH789PH789&biw=1010&bih=652&tbm=isch&sa=1&ei=aPxGW-KBK9q6rQHqqK7YBg&q=warship+in+shipyard&oq=warship+in+shipyard&gs_l=img.3…21972.24089.0.24790.12.12.0.0.0.0.438.2073.0j2j4j1j1.8.0….0…1c.1.64.img..4.4.769…0j0i67k1j0i30k1j0i8i30k1j0i24k1.0.BCHMZWftSsY#imgrc=Wo3V-gp1bI7ojM:

- https://en.wikipedia.org/wiki/Marine_propulsion

- Herma Shipyard, Mariveles, Bataan

- Cebu Shipyard, Lapu-Lapu City, Mactan.