INTRODUCTION

This article is a review notes in naval architecture and marine engineering simplified in outline form for quick reference how the forces of nature interact against a ship’s speed of advance at sea while underway.

SHIP HUSBANDRY

Hull Cleaning Program – a clean hull of the ship below the waterline makes a ship travel faster, uses less fuel and also benefits from reduced docking costs, has reduced risk of speed performance, as well as reduced wear and tear on the ship hull and engine. The ship can then move quickly and efficiently to reach its destination. The vessel’s overall cost is reduced, while its earning potential and mission performance is increased.

A naval vessel is a national investment in security.

- She needs to be in a state of readiness at all times.

- She needs to serve her country efficiently.

- She needs to be in tip top condition.

- She needs to save lives.

Why is a Ship Hull Overlooked?

- It is out of sight

- Who really understands marine fouling?

- It is a hidden cost

- Who really cares?

NOW is the right time to start caring, saving money, and extending the life of your vessels.

It is never too late to start, but will inevitably will be costlier, if you don’t. It is just makes sense to save money and increase vessel performance.

A merchant Marine Ship is a Business Investment

- She needs to sail at minimum possible time and travel economically.

- She needs to generate income to support operations, maintenance, profit, life extension program, etc.

- She needs to reduce her life cycle cost to the minimum.

- She needs to comply with standard ship classification rules periodically.

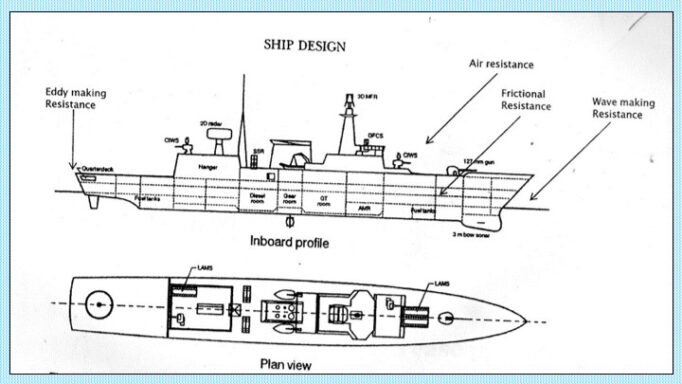

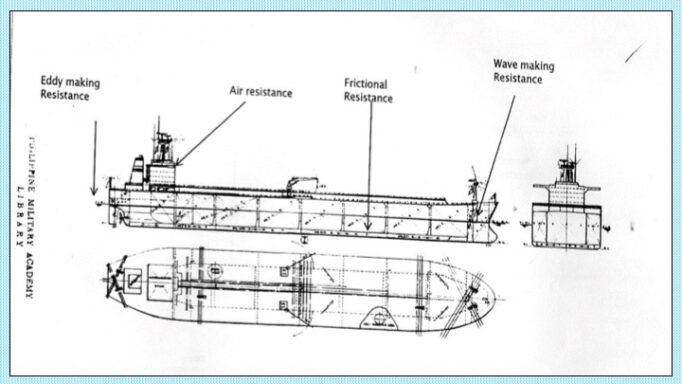

The 4 Natural Forces Acting on a Ship

- Wind NO CONTROL

- Eddy NO CONTROL

- Frictional CAN CONTROL

- Wave NO CONTROL

Wind Resistance – is a force that is caused when a ship moves against the wind. Any form of wind action on a vessel leads to air resistance. Air resistance is a kind of friction (a force that opposes motion) which occurs between air and another object such as a ship. It is the force that the ship experiences as it passes through the air.

Eddy Resistance – a drag force caused by an Eddy current that is shed from the hull of the ship or appendages of the ship, and opposed to the ship’s speed of advance.

Wave Making Resistance – a form of drag that affects the surface ship and reflects the energy required to push the water out of the hull. This energy is what creates the waves.

Frictional Resistance – is the largest part of the total resistance. The frictional resistance depends on hull surface roughness due to fouling and coating degradation. It also creates a drag, and opposed to the ship’s speed of advance.

Rf – Frictional resistance of fluid

S – The Hull’s wetted surface area in contact with sea water

V – Velocity of the hull

F – Constant depending on length and nature of surface.

OBSERVED HULL CONDITIONS AND ACTIONS

| Schedule of Inspection | Observations of Underwater Hull | Action Options | Consequences |

| 6 months from undocking | No serious blistering

Significant unbroken blisters |

Clean hull when required

Recognize ship as possible future risk |

None

None |

1

| Schedule of Inspection | Observations of Underwater Hull | Action Options | Consequences |

| Prior to first underwater cleaning |

No serious blistering but some hull fouling (FR-60) or greater. |

Clean hull

Clean hull

|

None

Possibility of rupturing blisters, increasing corrosion and refouling. |

| Significant blistering and some hull fouling (FR-60) or greater

Paint not visible due to fouling.

FR: fouling rate |

Do not clean hull

Clean hull |

Reduce chance of corrosion; increasing fuel penalty due to continued fouling.

If no blisters, no danger, if blistered, possibility of rupturing blisters, increasing corrosion and refouling

|

|

| Schedule of Inspection | Observations of Underwater Hull | Action Options | Consequences |

| After first cleaning | Wear of paint on edges and welds; no blisters

Significant ruptures blisters and rust staining |

Reinspect prior to next cleaning

Reinspect prior to next cleaning

Remove ship from cleaning program and plan near-term drydocking to repair paint

Or

Continued scheduled cleanings, no dry-docking

|

None

Possibility of rupturing blisters with future cleaning

If drydocked quickly, none

Or

Moderate fuel penalty; but increasing hull corrosion |

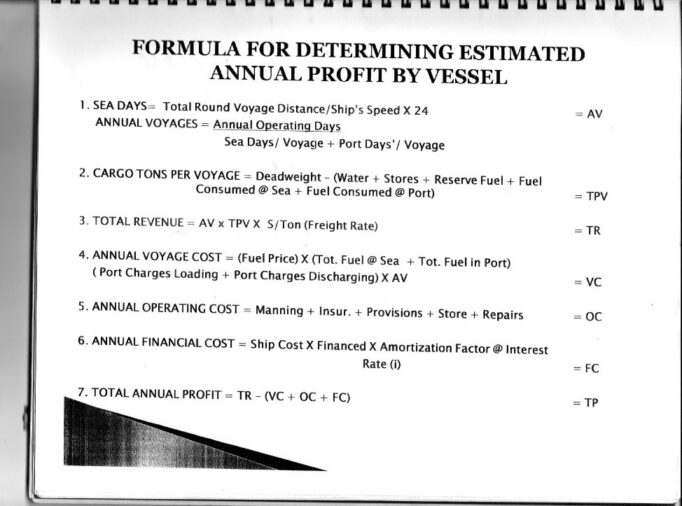

FORMULA FOR DETERMINING ESTIMATED

ANNUAL PROFIT BY VESSEL

ABOUT THE AUTHOR

CAPT BAINO is a registered naval architect and civil engineer in the Professional Regulation Commission in the Philippines. A former instructor in Basic Naval Architecture Stability and Trim at the Naval Officer Qualification Course at the Naval Training Command of the Philippine Navy and Basic Naval Architecture at the Philippine Military Academy, Baguio City. Likewise, his part time job is also to teach Basic Naval Architecture at NAMEI Polytechnic Institute. He was the former Commanding Officer of the Naval Shipyard, Philippine Navy and was involved in co-production of the 78 Foot Gunboat with Halter Marine Shipyard of USA and Patrol Craft Escort Refit Program of the Philippine Navy and Joint United States Military Advisory Group.

Upon his retirement from the NAVY in 2004, he served as consultant with BFAR for the acquisition of Fishery Monitoring Control Vessel from Spain and also with DOTr for the acquisition of 12 Multi-Role Response Vessel for the PCG under JICA Loan Grant. He served also with Development Bank of the Philippines Maritime Leasing Corporation in 2006 for local construction of RORO Vessel.

He earned a post graduate diploma in Naval Architecture at the University College of London specializing in Submarine Design under the sponsorship of UK Ministry of Defense and training in Hydrodynamic with Defense Evaluation Research Agency also in UK. He had also undergone orientation seminar with Blomh and Voss in MEKO Warship Design and Construction in Hamburg, Germany.

References:

- Royal Institute of Naval Architecture

- Modern Ship Design by Thomas Gilmer