INTRODUCTION

This article is a detailed overview on how the propulsion system of 44M Multi-Role Response Vessel of the Philippine Coast Guard PMS can be achieved. The existing propulsion system of said ten units 44M MRRV is MTU Model 12V 4000 series M93L which can be maintained effectively using the following step by step PMS procedures:

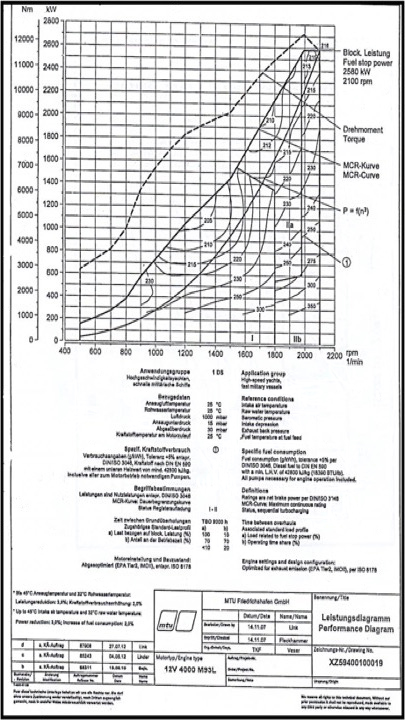

- Understanding the engine performance curves of the engine speed and power performance limitation as shown in Fig 1.

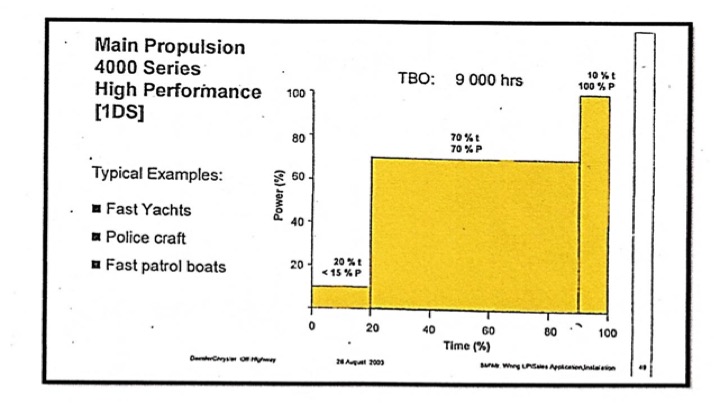

- Meantime Between Overhaul of 9000 operating hours at 61% average load factor (life span of engine)

- Power Rating Capacity of 2,580 brake horse power at 2,100 rpm.

- Operating temperature of air and water are 25oc

- Speed and power performance limitation

- 100% power load at 10% of the operating time duration

- 70% power load at 70% of operating time duration

- Not greater than 10% power load at 20% operating time duration

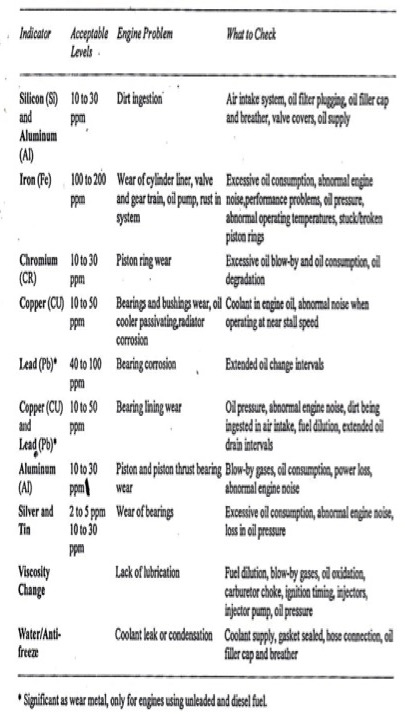

- Frequent lube oil analysis

- Fuel compatible to the engine

Table 1

SPEED, POWER, TIME ALLOWABLE AND TACTICAL OPERATION

| Load/Power Rating | Operating Hours Allowed / Patrol Time | Bhp | Speed/Time Allowable | Average Load Factor |

| 100%

Interception/hot pursuit |

10% | 2 x 2,580 kw | 25 knots for .60 hours only

(36 minutes) |

.10 x .01 = 0.010 |

| 70%

Cruising/patrolling |

70% | 2 x 1,806 kw | 17.5 knots

for 4.2 hrs. |

.70 x .70 = 0.490 |

| <10%

Maneuvering/ loitering |

20% | 2 x 258 kw | 2.5 knots

for 1.2 hrs. |

.10 x .20 = 0.02 |

| Average allowable time and load factor | 6 hours | 0.52 or 52% not greater than 61% | ||

Note: 1) Average load factor is the amount of power imposed in the engine and the measure of level of stress absorbed by the engine.

2) TBO-Time Between Overhaul is the life span of the MTU Model 12V 4000 M93L series before next major overhaul is conducted which is limited to 9000 hours only at maximum 61% load factor. Exceeding the load factor will diminish or shorten the TBO of the engine, and premature engine failure breakdown will occur.

Figure 1

Performance Curve of Marine Diesel Engine MTU

MODEL 12V 4000 M93L SERIES

Figure 2

Diagram of Desired Operating Profile as Recommended by MTU Engine Manufacturer

Table 2

Fuel Specification to be Complied by the PCG (Recommended by MTU Engine Manufacturer)

| Composition | Limiting Values |

|

24 Mg/Kg |

|

0.820 g/ml |

|

41 to 33 |

|

1.5 mm2/s |

|

550C |

|

.30% by weight |

|

0.01% by weight |

|

0.5% by weight |

|

45 |

|

42 |

|

25g/m3 |

Table 3

Predicted Engine Problems thru Spectrometer Oil Analysis

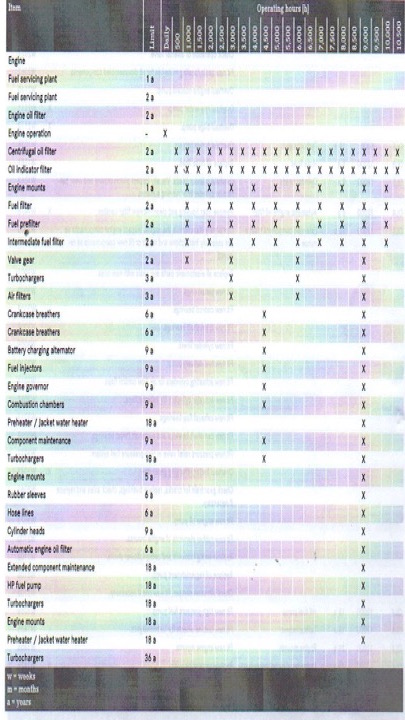

Table 4

Planned Maintenance System Matrix of 9000 Hours MTBO

*schedule of spare replacement versus time utilization due to wear and tear

RECOMMENDATION

In order to hone the skills of new PCG shipboard personnel, PCG must conduct periodic training sessions through lecture series. Understanding the performance curves limitation, the schedule of spare parts replacement, periodic oil analysis with real time application, and utilization of the recommended quality of fuel can ensure that the meantime between overhaul of 9,000 hours can be fully achieved at 61% load factor by Series Model of Engine MTU 12V 4000 M93L.

References:

- http://defenseph.net/drp/index.php?topic=1726.0

- MTU Engine Model 12V 4000 m93L Series Technical Manual Proposed Circular of Requirements (COR) of 44M MRRV.

About the Researcher

CAPT TOMAS D BAINO PN (Ret) served as Naval Architect Consultant with the Project Management Office in Ship Acquisition, Operations and Maintenance from 2017 to 2020 of the Philippine Coast Guard and Department of Transportation.

CAPT TOMAS D BAINO PN (Ret) served as Naval Architect Consultant with the Project Management Office in Ship Acquisition, Operations and Maintenance from 2017 to 2020 of the Philippine Coast Guard and Department of Transportation.

Lecture series has been conducted on said aspect of the Planned Maintenance System (PMS) of said engine to the PCG that requires periodic training.