INTRODUCTION

Propulsion is a means of creating force leading to the movement of a vehicle in the water, air or in land. The term is derived from Latin word “pro” meaning before or forward, and “pellere” meaning to drive. A propulsion system consists of the source mechanical power, and propulsion to convert the power into propulsive force.

The main engine of a ship is connected to its propeller thru the shaft. This system is used to provide speed and power to the ship efficiently.

Marine propulsion is the mechanism or system used to generate thrust to move the ship or boat across the surface or underwater. Marine engineering and naval architecture go hand and hand and their discipline is concerned with the design of marine propulsion system, for both ship and submarines.

The concern of the naval architect is to provide strong foundation attachment to the engine and reduce the frictional resistance of the hull, which if not corrected could result in power losses to the engines.

In contrast, the concern of the marine engineer concentrates on providing the power demand of the ship at the most economical means (lower fuel consumption), operation and maintenance.

Today, the primary source of the propeller power is the marine diesel engine and the power requirement and rate of revolution of the propeller is very much dependent on the ship hull form (planing, semi-planing, and displacement type) and the propeller design. This article will, in particular, explain briefly some of the most basic parameters in the choice of the best-suited propulsion marine diesel engine for a specific type of ship, for which the Philippine Navy (PN) and Philippine Coast Guard (PCG) could adopt as a template. This article will only concentrate on the surface ship propulsion design.

3 ENGINE TYPES AND APPLICATIONS

- Low Speed Engine (95-500 revolutions per minute). This is a large marine propulsion engine, with a direct coupled or geared reduction drive to the propeller. This type of engine is used in large displacement type vessel.

- Medium Speed Engine (500-1000 revolutions per minute). This has a geared-reduction or diesel electric drive. This type of engine is used in semi-displacement type vessel.

- High Speech Engine (over 1000 revolutions per minute). A geared reduction gear. This type of engine is used in planning type vessel.

SELECTION PARAMETERS

- Rated Power – the power needed by the ship to propel in the water efficiently.

- Economy of Operation – Minimum fuel consumption at various engine load factors.

- Meantime Between Overhauls – the engine must have the aptitude of longer top over role.

- Availability of Spare Parts and Service Center – to maintain the availability and readiness of the engine, it must have a local service center and spare parts supplier.

- Climate Condition – the engine must be capable to adapt to the area of operation, climate condition, and must not degrade or encounter functionality degradation.

- Environmentally Friendly – the engine must have low emissions of carbon monoxide so as not to pollute the environment.

- Special Tools – the engine must have a commonality of tools that can be used in a similar type engine.

- Life Cycle Cost – the engine must have low life cycle cost in terms of operation and maintenance.

- Scheme of Overhauling – the engine must have the ability to be overhauled onboard the ship in order to lower the maintenance cost.

- Power to Weight Ratio – the engine must be as light as possible in order to lessen the weight of displacement of the ship.

- Availability – the engine must have longer operating time at minimum load factor.

- Acquisition Cost – the engine must be competitive in terms of cost of acquisition.

- Operating Profile – this is one of the critical points of the selection process in order to identify the engine compatible to the operation and maintenance doctrine of the propulsion system.

- Engine Load Factor – a characteristic of the engine to provide wide spectrum of operation utilizing minimum engine power load while at the same time achieving the various speeds and power requirement, without subjecting the engine to excessive stress.

MARINE DIESEL ENGINE PERFORMANCE CURVES

The performance curves of every Marine Diesel Engine indicate the power output, fuel consumption data, and the engine speed in Revolutions per Minute. The performance curve shows the following:

- Brake Horsepower (BHP) – this is the power available at the engine flywheel.

- Shaft Horsepower (SHP) – the net power available at the output shaft of the marine gear after consideration of frictional losses through the gear, and parasitic losses from the standard driven accessories (alternator, raw water, pump, etc.)

- Propeller Load – the theoretical horsepower absorbed by a typical fixed pitch propeller which has been designed to absorb the engine pull power output at its rated speed.

- Fuel Consumption – the indicated amount of use when the engine develops power according to the performance curves.

- Fuel – propeller load provides fuel consumption when the engine develops power according to the curve; when actual propeller demand exceeds the theoretical propeller load, the fuel consumption increases proportionally.

LOAD FACTOR OF MARINE DIESEL ENGINE

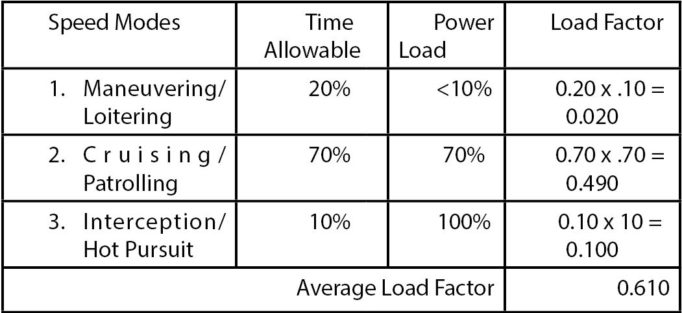

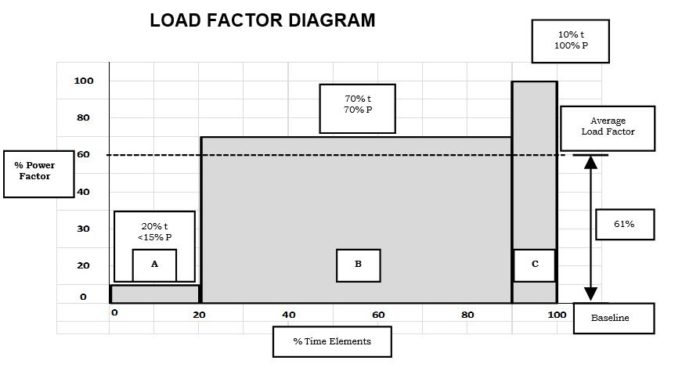

Load Factor is the amount of fuel burned over a period of time divided by the full power fuel consumption over the same period of time. The higher the fuel, the higher the speed and power imposed on the engine.

The Operating Profile of the vessel is very important in order to preserve the life span and availability, readiness and reliability of the Marine Diesel Engine. The said Operating Profile will allow the engine to conserve its rated power without undue stress to the internal combustion system of the engine. This has a significant effect on the periods of Meantime Between Overhauls (MTBO). The stated overhauls were based on the adopted Operating Profile and operated at various engine load profile. The higher the load factor, the sooner the engine will require an overhaul (MTBO time allowance exhausted).

Some Marine Diesel Engine limitation has some restriction. For example:

Operations Profile and Load Factor

- Operations Profile:

- 30 Days Deployment at AOR = 720 hours

- Meantime Between Overhaul of Engine = 9,000 hours

- Operation Mode of Propulsion Engines

- Load Factor = 0.610 x 100%

- = 61.00%

- Usable Power (Theoretical)

- = 2,580 KW x 61.00%

- = 1,573.80 KW

- Meantime Between Overhaul (MTBO)/Deployment

- = 720 hours x 0.610%

- = 439.20 hours

- Ship Operation Time at Sea

- = 720 hours

- Time Utilize for the Engine

- = 439.20 hours x 6 Deployment/Year

- Number of Years Before Overhaul

- = 9000 hours/2,635.20 hours

- (Average)/Years = 3.415 Years

LOAD FACTOR DIAGRAM

Recommendation:

Adopt the foregoing basic selection parameters in choosing propulsion engines for combatant and non-combatant vessels for the Philippine government.

References:

Detroit Marine Diesel Engine

MTU Marine Diesel Engine

Wikipedia